Centrifugal Oil Cleaning Systems, Manufacturer, Exporter, Supplier and Dealer. Our setup is situated at Pune, Maharashtra, India

Why Centrifugal Oil Cleaner

Centrifugal Oil Cleaner removes very fine dirt from Oil upto 1µ and below, by Centrifugal force created in centrifuge rotor. Conventional filters can not remove such fine dirt from oil. There are no consumables hence no recurring cost. Collected dirt can be easily cleaned and the unit put back to use again. With clean oil, wear of tools and dies is reduced and job finish is improved. The oil need not be replaced frequently, thereby saving substantially on oil expenses and protecting Environment.

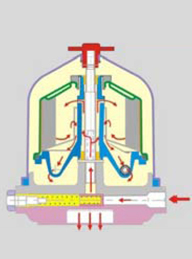

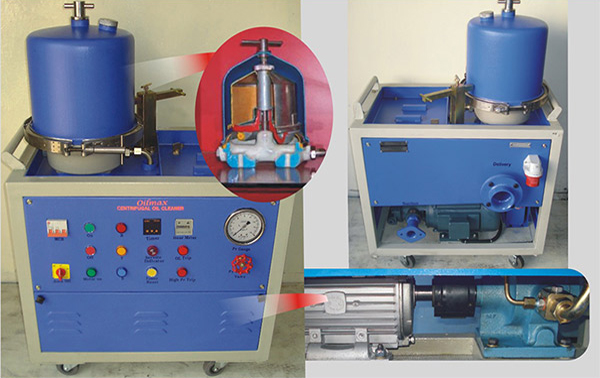

Working Principle

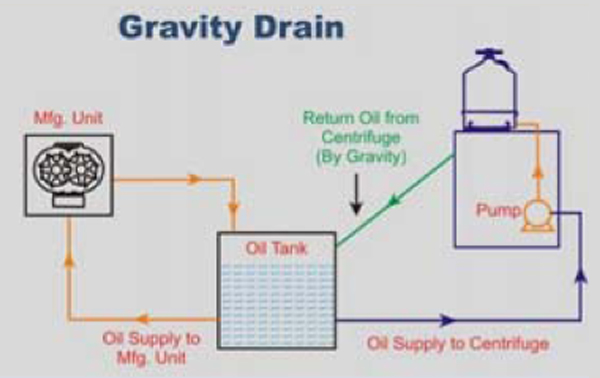

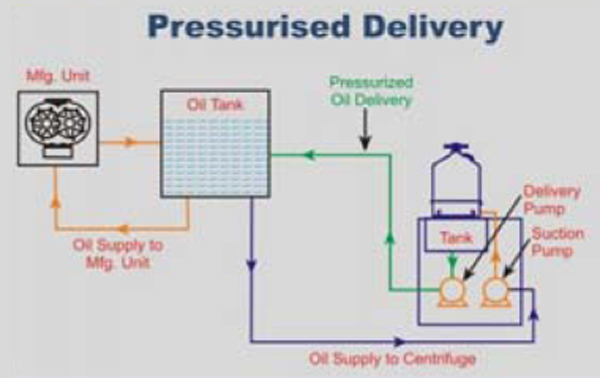

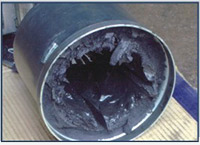

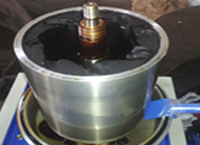

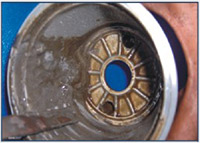

Centrifugal Oil Cleaner works on reaction turbine principle. Oil enters Centrifuge under pressure and escapes through tangentially opposite Nozzles of rotor producing rotor speed upto 8000 RPM. The resultant Centrifugal force removes dirt from the oil, depositing it on the inner wall of rotor in a dense cake form. Clean oil drains back to the oil tank by gravity.

Schematic Diagram

Construction

Salient Features :

- No Filter Element

- No Replacement Cost

- Improved Product Finish

- Reduced Oil Consumption

- Extended Oil Change Period

- Reduced Machine downtime

- Reduced Storage & Disposal Cost of Waste Oil

- Reduced Pollution and Environmental Impact

Applications :

- Wire Drawing

- Gear Boxes

- Cutting Oil

- Transmission Oil

- Cold Forging

- Cement Mills

- EDM Oil

- Compressor Oil

- Fastener Mfg.

- Coal Mills

- Spindle Oil

- Bio Diesel / WVO

- Heat Treatment

- Crushers

- Hydraulic Oil

- Anti Rust Oil

- Bright Bar Mfg

- Transmissions

- Gear Oil

- Stamping Oil

- Thread Rolling

- Marine Engines

- Turbine Oil

- Honing Oil

- Super Finishing

- Port Equipments

- Engine Oil

- Quenching Oil

- Honing

- Mining Equipments

- Furnace Oil

- Water Emulsions

- Grinding

- DG Sets

- Thermic Fluid Cleaning Systems

- Test Bed Oil

Installations

Quenching

Cold Forming

Furnace Oil

Cement Plant

Tube Mill

Anti Rust Oil

Thermic Fluid

Special Purpose Machine

| Oil Cleaning System Model | Nominal Flow Rate | Dirt Holding Capacity | Dimension (W x D x H) inch |

| OCS 500 | 500 LPH | 500 cc | 22 x 12 x 30 |

| OCS 750 | 750 LPH | 1000 cc | 22 x 12 x 33 |

| OCS 1500 | 1500 LPH | 2000 cc | 24 x 13 x 38 |

| OCS 4000 | 4000 LPH | 6000 cc | 30 x 18 x 44 |

| OCS 8000 | 8000 LPH | 12000 cc | 33 x 28 x 44 |

| OCS 1000P | 1000 LPH | 1000 cc | 28 x 18 x 36 |

| OCS 1500P | 1500 LPH | 2000 cc | 30 x 20 x 38 |

| OCS 4000P | 4000 LPH | 6000 cc | 33 x 23 x 44 |

Sludge Collected in central

Aluminium Wire Drawing

Bright Bar Mfg.

Nut / Bolt Forming

Quenching

Gear Oil

Hydraulic Oil

Transmission Oil

Thermic Fluid

Furnace Oil

Engine Oil

Bio Diesel

Rust Preventive Oil