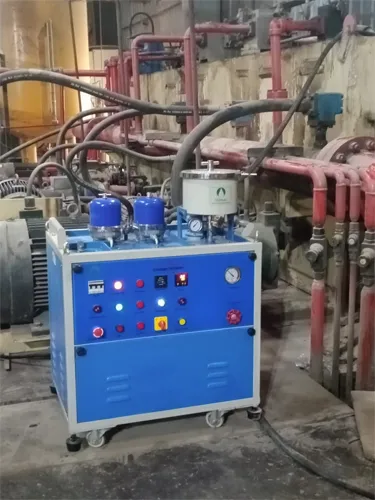

Hydraulic Oil Cleaning Systems, Manufacturer, Exporter, Supplier and Dealer. Our setup is situated at Pune, Maharashtra, India

Salient Features :

- Fine Filtration up to 1µ

- Reduced Component wear

- Reduced Oil Consumption

- Extended Oil Change Period

- Reduced Machine downtime

- Reduced Storage & Disposal Cost of Waste Oil

- Reduced Pollution and Environmental Impact

Save by Extending Oil Life and Equipment Life

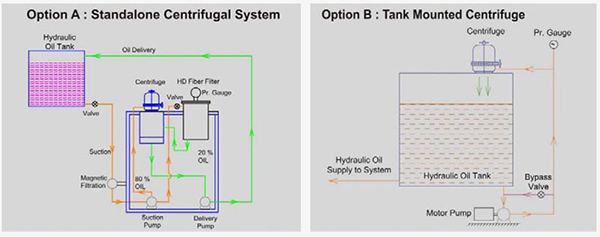

Centrifugal oil Cleaner removes very fine dirt from Oil upto 1µ & below by Centrifugal force created in centrifuge rotor. Conventional filters can not remove such fine dirt . Collected dirt can be easily cleaned & the unit put back to use again

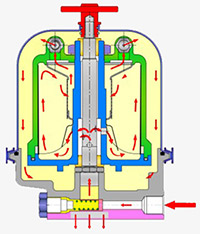

Working Principle

Centrifugal Oil Cleaner works on reaction turbine principle. Oil enters Centrifuge under pressure and escapes through tangentially opposite nozzles of rotor producing rotor speed upto 8000 RPM. The resultant Centrifugal force removes dirt from the oil, depositing it on the inner wall of rotor in a dense cake form. Clean oil drains back to the oil tank by gravity.

Schematic Diagram

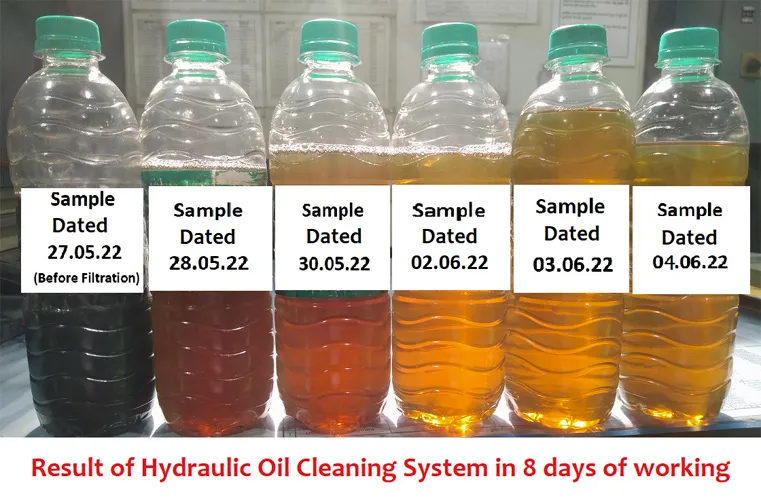

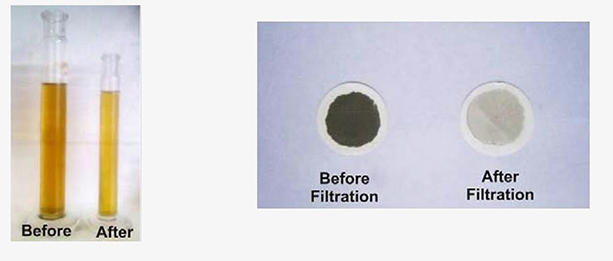

Hydraulic Oil Patch Test

Portable Unit - HD Fiber Filter

Salient Features :

- Filters down to 1 micron

- Removes free and dissolved water

- Cleanliness : ISO 14/11, NAS 5-7

- Water holding capacity 900cc

- Extends oil and component life

- Reduces Failure of hydraulic System

- Suitable for tank capacity up to 400 Ltrs.

- Replaceable Filter Cartridge

Applications :

- Hydraulic Power Packs

- Hydraulic Cranes

- Injection Moulding Machines

- Hydraulic Press

- Steering Gear

- Framo System

- Thruster

- Deck Machinery (Winch, Windlass)

Unique Three Stage Filtration Process

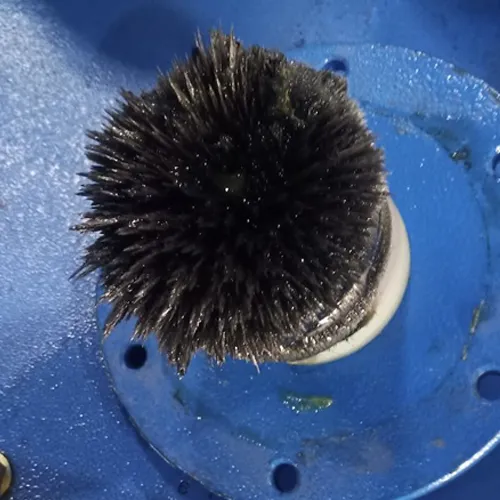

- Stage1 - High power rare earth magnetic filter to trap ferrous particles

- Stage2 - Specially designed inverted rotor centrifuge which is consumable free and reusable. It will trap majority of contamination to level up to 1 micron

- Stage3 - Very fine depth filter to remove particles down to 0.1 micron and to absorb moisture

Stage1

Stage2

Stage3

Installations