Chip Compactors, Manufacturer, Exporter, Supplier and Dealer. Our setup is situated at Pune, Maharashtra, India

Since many years in Machine Shop Cutting tools & coolant is used during machining process. During the machining process a lot of cutting oil (coolant) is also wasted and chips or grinding dust is produced in large quantity. These chips are collected in trollies & moved to scrap yard. Huge space in scrap yard is utilized for this conventional chip storage method With the help of Chip Compactor we can save space as well as reuse oil & coolant with the help of machines with. We can rrecycle oil and coolant along with maximum use of space by using Oilmax Chip Compactor.

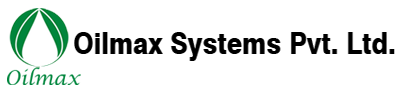

Large amount of chips in machine shop are generated and lots of oil & Coolant is also wasted. Solution to this is separation of oil / coolant and recycling of loose chips. To serve these purpose, we have developed a Chip Compactor Machine. Because of this product manufacturer can save cost of maintenance of scrapyard and transportation cost of loose chips. This Chip compactor compacts loose chips into a dense briquettes, it has become very easy melting these dense briquettes instead of loose chips.

Chip Compaction

Grinding Dust Compaction

Installations

Our Valuable Clients

Specifications

Model |

VCC12-110 |

VCC12-150 |

briquettes Size in ∅ |

∅ 100mm x 50 mm |

∅ 100mm x 50 mm |

Hydraulic Force |

110 T |

150 T |

Electric Motor |

15 HP |

15 HP |

Cycle Time |

23 Sec |

20 Sec |

Machine Size (LxWxH) in mm |

1700 x 900 x 2200 |

1700 x 900 x 2500 |

Special Features

Features |

Details |

Auto Stop |

Machine stops automatically if chips are not available in hopper |

Coolant / Oil Collection |

Coolant collection tank with delivery pump can be provided |

Hopper size |

There is option of screw conveyor with bigger hopper capacity (400-500 KG or more) for loading higher volume of scrap. |

HMI / Operating Panel |

7” HMI / Screen is provided which is very user friendly. The working cycle is continuously displayed on the HMI & will show fault if occur |

Feeding Auto Stop |

The feeding conveyor can be stopped when hopper is filled up fully through auto stop feeding mechanism |

Crusher, Conveyor & Hopper |

There is option of crusher for lengthier chips, conveyor & hopper to avoid manual interference |

Advantages of using Chip Compactor :

- Storage : Hygienic chip storage with Reduction of storage space by 75 or 85%

- Accountability : Accountability of chips for monitoring

- Transportation Cost : Reduction in transportation cost

- Selling Cost : High selling cost of scrap as it is dried

- Reuse of Oil & Coolant : Almost 90% oil/coolant can be recovered and can be reused which is going along with the scrap

- Reduction in power consumption : Compacted bricks can directly fed in to furnace hence there will be low power consumptions in foundries

- For Smelters & Melters : Less surface area to oxidize and become slag.

- Furnace Utilization : Will reduce melting time which increases Furnace Utilization. Fumes & Blasts are avoided in furnaces

- Pollution control : Contribution to reduce industrial pollution